When renting access platforms, choosing the right one is critical to the success and safety of any work-at-height project. With a wide range of machines available, it’s important to match the right MEWP to the job, site conditions, and access requirements. Whether you’re planning a project or doing a last-minute repair at height, selecting the right access platform can make all the difference.

In this guide, we’ve consulted our team and IPAF-qualified training instructors boasting decades of experience to walk you through the key factors when selecting a MEWP to ensure efficiency and safety.

Understand the Type of Work and Site Conditions

An obvious start, but when doing a site survey or looking to get a hire quote for a new job, assess the task at hand and the environment you’ll be working in. Ask yourself:

- What height and outreach are required?

- Is the work indoors, outdoors, or both?

- Are there any obstacles to navigate around or over?

- What’s the ground surface—smooth concrete, uneven terrain, or a delicate floor?

For example:

- Indoor fit outs with limited space or low-load-bearing floors may call for narrow electric scissor lift or a push around vertical.

- Outdoor installations with uneven ground may require diesel-powered boom lifts with oscillating axles or rough terrain scissor lifts with outriggers.

Know the Main Types of MEWPs

Those who work at height regularly will more than likely understand the core MEWP categories. But for those who’ve just passed their IPAF operator training or MEWP for Managers course, the following may be a useful reminder. Those completely new to hiring MEWPs, make sure you have the right training and seek help with MEWP selection.

- Scissor Lifts: Ideal for vertical access and jobs needing a larger working platform—perfect for maintenance or multi-person tasks.

- Boom Lifts (Articulating & Telescopic): Best for up-and-over or outreach tasks, such as accessing hard-to-reach façades or roof areas.

- Personnel Lifts/Vertical Masts: Compact, low-weight machines great for tight access indoor jobs with limited floor load tolerance.

- Spider Lifts/Tracked Boom Lifts: Excellent for sites with narrow access points or delicate flooring; often used in retail or atrium areas.

Consider Power Source Requirements

Your job’s location will determine the power type that suits your task best. For example, if you’re in a new warehouse build, is there any power available to recharge electric MEWPs? Are you working indoors in a confined, unventilated space where diesel fumes pose a significant health risk?

- Push Arounds, Personnel Lifts, and Electric MEWPs: Quiet, fume-free, and ideal for indoor use.

- Diesel MEWPs: Offer power and endurance for outdoor or longer jobs but may not be suitable for noise- or emission-sensitive environments.

- Hybrid or Bi-Energy MEMPS: Provide flexible operation indoors and out.

Factor in Weight and Access Restrictions

Some job sites have tight access, weight limits, or restricted entry points. This example is extreme, but if you’re working indoors repairing lights above on a mezzanine floor in a factory, you’re not going for a heavy 40ft (12m) diesel scissor lift, you’re likely to go for a push around platform. The last thing you need is project downtime or cancellations because of choosing the wrong machine, so consider:

- Machine dimensions and stowed height (can it get through doors or lifts?)

- Weight limits on floors or lifts (important for mezzanine or shopping centre jobs)

- Any need for non-marking tyres or low-emission zones

Planning for these constraints ensures you won’t face delays or additional costs on delivery day. Our guide ‘5 key questions To Ask Before Hiring An Access Platform‘ will help further.

Think About Operator Comfort and Safety Features

Safety doesn’t stop at machine selection; it extends to features that make working at height more stable and secure:

- Platform capacity to support workers, tools, and materials

- Guardrails, harness points, and secondary guarding

- Outriggers on diesel scissor lifts or oscillating axles on a boom on uneven ground

- Effective anti-entrapment considerations

Regulations such as Work at Height Regulations 2005 and Provision and Use of Work Equipment Regulations (PUWER) 1998 state the need for planning, competence and risk assessments when working at height with equipment. So don’t forget to ensure operators are properly trained and certified to use the equipment. IPAF training is the most recognised way in the UK to stay compliant when using MEWPs.

Need Help Choosing the Right MEWP?

Horizon Platforms supply customers with MEWPs who work across many industries including shopfitting, electrical installation, facilities management and many more. And, since 2008, we’ve built deep expertise in powered access, earning key accreditations like IPAF Rental+, SafeContractor, and multiple ISO certifications. Having supported and trained thousands of companies, we understand real-world work-at-height challenges.

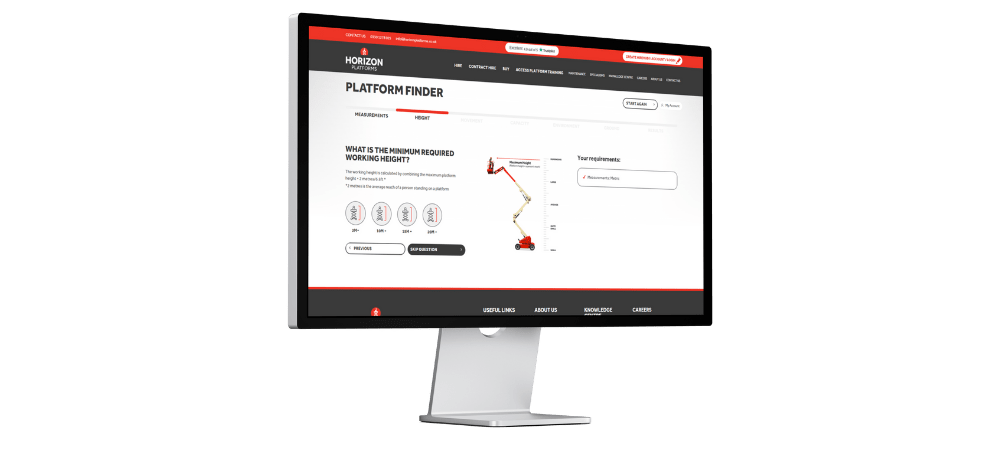

With Horizon you have a couple of options if you need a hand choosing a MEWP for your next project. Either call or email our team or use our online tool, Platform Finder.